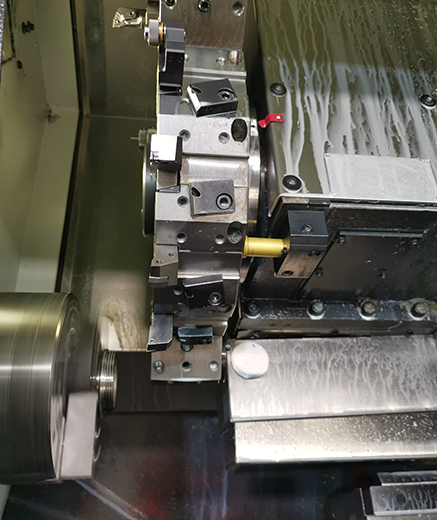

Silverfall offers various CNC Machining capabilities to perform complete and complex machining to your die casting parts. All of our die casting machining fixtures are designed and built in house, allowing for a high degree of customization and short lead time.

We have Japan “TAKISAWA” CNC lathes, Taiwan “GOODWAY” CNC lathes, Japan “BROTHER” CNC horizontal machine centers and vertical machine centers. These machine centers have spindle speeds up to 18000 rpm and feature high pressure coolant and 4th axis capabilities. Equipped with high speed pallet shuttle systems, cycle times are greatly reduced, allowing us to maximize efficiency and save much cost.

CNC Milling (4 Axis CNC M/C) & CNC Lathe Machining

Drilling - ±0.01mm Tolerance

Reaming - ±0.01mm Tolerance

Tapping - All Kinds Of Threads Standards, UNC, UNF, NPT, BSPT,BSPP, etc. Threads Vertical 90°±0.5°

Grinding - Horizontally And Cylindrically To Standard Grinding Tolerance

Bead Blasting/ Shot Blasting

Impregnation

Irridite/ Chemical film/Conversion Coating

Anodizing

Powder Coating

Painting

Sanding, Buffing and Polishing

Nickel, Copper Plating, etc.

Other Finish As Per Customers Requirements