SilverFall is a quality driven company with strict QC procedures to ensure our customers' maximum satisfaction. We promise delivery of quality die casting and machining products through process development and advanced product quality planning (APQP). Quality Control is built into the process handling with a series of inspections and various testing equipments to strengthen products' reliability and to make sure that all products are defect-free when they leave our production plants.

All raw materials must be inspected by independent material testing institute before being used in the production.

QC inspections are performed at each stage of production.

Random inspections are also conducted every day.

A final inspection is conducted before delivery is authorized.

Series Digital Gauges, Micrometers & Calipers

Go/No Go Guages For Threads

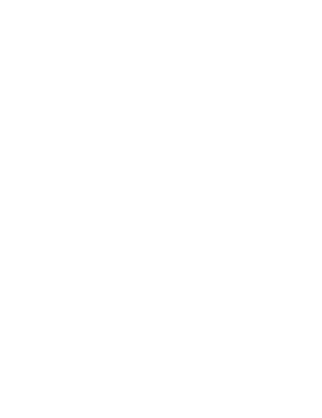

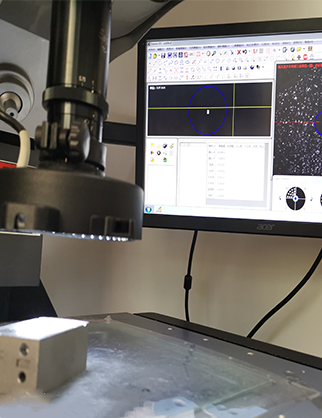

HEXAGON 3-Coordinate Measuring Machine

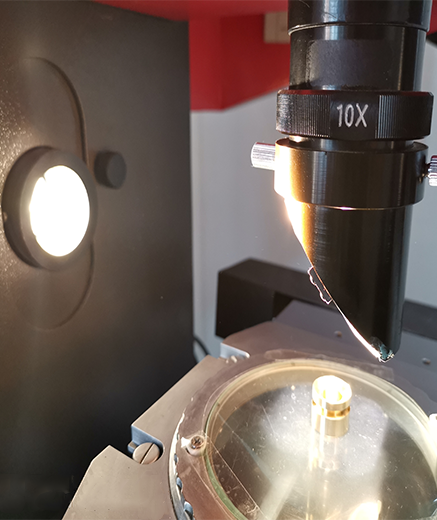

Digitizing Measurement Profile Projector

MITUTOYO Surface Roughness Measuring Instrument

Spectrographs & Computerized X-ray Machines